Manufacturing Solutions

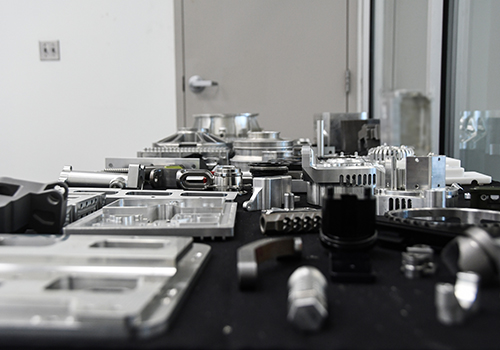

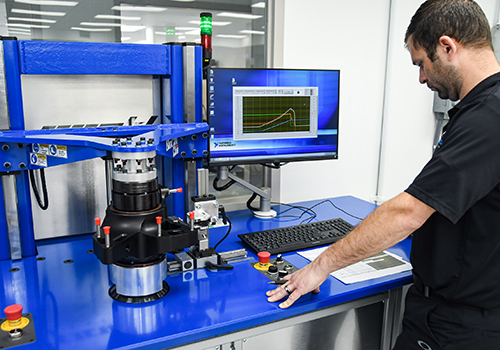

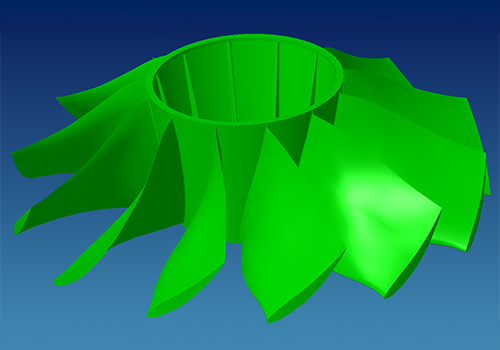

Roush Yates Manufacturing Solutions’ engineering team consists of highly skilled engineers, programmers, and CNC machinists that are ready to guide you through the product concept to CNC manufacturing process. They are experts in part design and analysis, designing for manufacturability, and developing solutions for prototype and production volume parts. As a leader in CNC manufacturing, we turn concepts into world-class products.

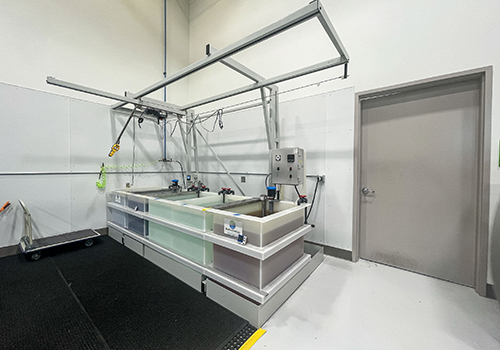

We utilize a vertical integration strategy which allows us to fully leverage the capability and capacity of each CNC machine in our two manufacturing facilities spanning 143,000 square ft. while leveraging the expertise of our engineering team. This in turn allows us to control process, reduce cost, and improve overall efficiencies. Roush Yates Manufacturing Solutions has delivered precision manufactured mission-critical components and assemblies for the aerospace, defense, space, medical, and motorsports industries. You can trust us to engineer the same great quality product for you.